ball nose end mill uses

Small diameter ball nose end mills are used for projects with intricate detail while larger bits are used. Otherwise the masses would not have purchased products from popular brands.

Ball Nose Milling Strategy Guide In The Loupe

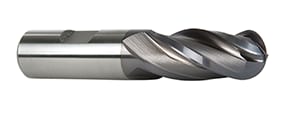

Solid carbide end mill with excellent cost-benefit ratio.

. 4 flute ball nose end mill with with AlTiN coating chipbreakers for slotting heavy profiling Nickel Based Alloys Hardened Materials 45 HRC 56 Willow Brook Drive Berlin CT 06037. A square end mill with a radius ground on the corner can provide a small radius at the juncture if reduction of stress is the desired objective. A ball end mill will produce a radius one half the diameter of of the tool used.

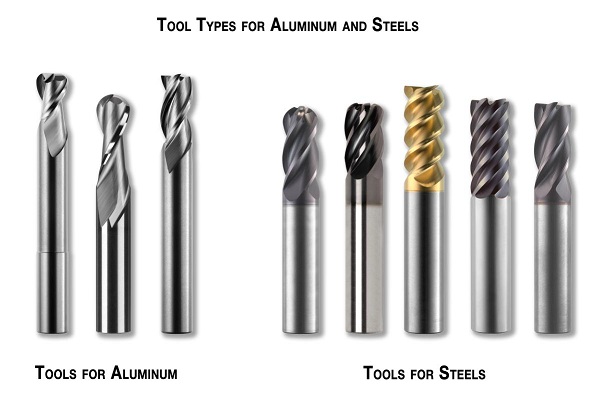

And they are not so great on milder material like aluminum either. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. FREE Shipping by Amazon.

These ball end milling bits also carry a. In fact they are classified as multi-functional tools owing to the various drilling boring or cutting functions they. Ball-Nose End Mills.

So consumers usually choose the brand that they have been longest associated with. Ball end mills also known as ball nose end mills or full-radius end mills have a constant single radius or ball at the end of the cutting tool. A ball nose milling cutter uses ball nose end mills and is similar to a slot drill though the ends are hemispherical.

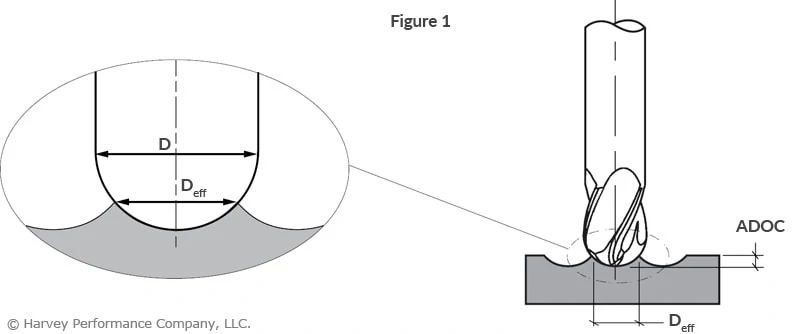

The ball nose end mill is used for profiling and the cutting depth and width are less than 01D. A photograph of the investigated WEBNHE is shown in Fig. In the ball nose end mills hss industry brand loyalty is very high.

Customers looking for quality ball nose end mills to purchase should therefore visit the website to sample and select these millingdrilling tools. 625 shows WEBNHE performing up milling operation. Ball Nose End Mills.

Ball-nose end mills have a dome-shaped tip. Made of solid carbide they are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. These ball nose end mill bits come in a wide array of shank and radius combinations with many different ball nose cutter sizes.

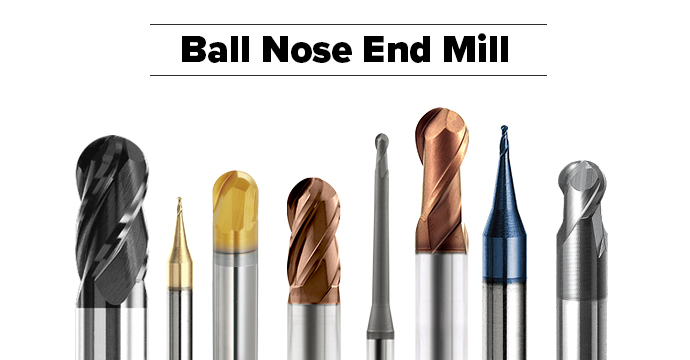

Ball nose end mills come in many different types and have many different uses. Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. In general ball nose and corner rounding cutters require more cutting pressure which results in a poorer finish on steel.

In periodic feed machining even if R is small it can also be used. Four or more fluted ball nose end mills have less chip evacuation due to their design but with multiple cutting. Ball-end milling is also known as copying milling because of the old practice of copy forms from jigs 40 years ago before the introduction of CNCs in milling machines.

Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece meaning less work for you as the piece wont need to be finished any further. If ya aint shootin ya aint dangerous. These excel at high-detail contours like relief artwork or mold and die making but have what is known as scalloping Since the tip of the end mill is round having a perfectly flat surface is a challenging feat and will take many more passes than a simple fishtail to smooth.

Sometimes they are called ball mills on the shop floor even though the term has another meaning. Eccentric relief increases cutting edge stability for long tool life and high surface quality. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

Read customer reviews find best sellers. Ball Nose Milling Without a Tilt Angle. Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional.

DATRON Ball Nose End Mills are excellent for milling smooth 3D surfaces even on complex shapes. M3Tools 18 3175mm Shank 14 Regular price. The end of this tool is ground with a full radius equal to half of the tool diameter and the edges are center cutting.

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Ad Browse discover thousands of brands. Not that they cant do a good a good job under the right circumstances but in general ball nose and corner rounding end mills are only for cosmetic.

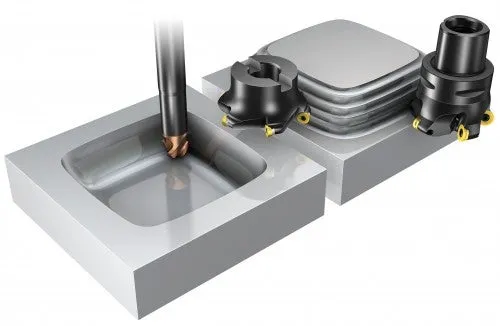

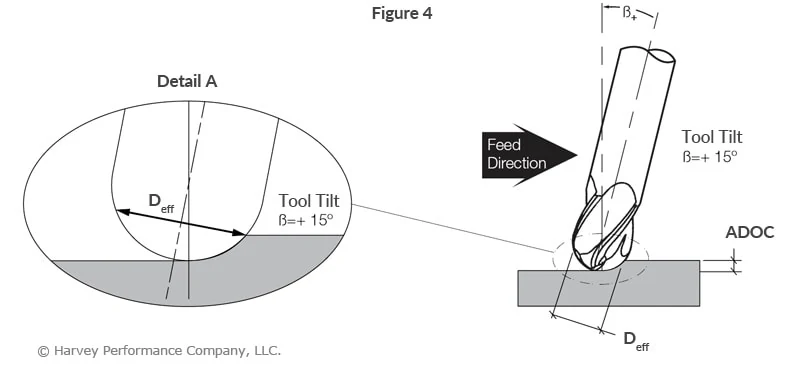

Only 11 left in stock - order soon. Mechanics of wavy-edge bull-nose helical end mill. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process.

Ball Nose End Mills. High-Speed Steel Ball End Mills Use these end mills for general purpose milling in most material such as aluminum brass bronze iron and steel. Stealth Arms Custom Ball Nose End Mill Cutter is used to cut the barrel set out of a 1911 80 Frame.

Popular brands guarantee reliability. A loaded spare magazine is a renewable energy source. SPEED TIGER ISB Carbide Ball Nose End Mill - Micro Grain Carbide End Mill for Alloy SteelsHardened Steels - 2 Flute - ISB5162T - Made in Taiwan 1 Piece 516 35.

Fast-Cutting Carbide Ball End Mills. 1PC Tapered Ball Nose End Mill. Get it as soon as Fri Jun 3.

I needed a two inch ball nose end mill to machine a couple dimples in an upcoming project so instead of buying an expensive tool that will likely never be us. The rounded cutting edge and being able to use the full radius of the tool makes it easy to cut material at any angle. Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines.

They are used for contour milling shallow slotting pocketing and contouring applications. Variable spacing between the flutes reduces vibration allowing these end mills to provide fast cuts smooth finishes and long tool life. Yonico solid carbide end mills are manufactured from the highest quality micro grain C3 solid carbide and will last for hours of use and maintain its sharpness throughout.

The cutting profile has no sharp corners or straight edges. Solid carbide end mill with stepped parallel shank according to DIN 6527. They can be single end or double end and they can be made from solid carbide or various compositions of high speed steel.

Corner Radius End Mill. Therefore they are suitable for machining any 3D contoured shapes into the machining centers such as dies and molds. The nose radius is equal to half the diameter of the tool and the edges are center cutting.

Different brands have different attributes. A ball end milling cutter is also known as a ball nose mill. Eccentric relief eases regrinding and reduces reconditioning cost.

Corner radius end mill is used for machining the corner R and periodic feeding. A must have when using the Stealth Arms 1911 Classic Jig in order to get the correct 350 radius on the frames barrel set. The ball nose end mill has the best effect on the machining curved surface but the chip discharge performance is poor because of the small chip holding groove at the tip.

Ball Nose And Bull Nose Inserts Work Well Together Sterling Edge

3 4 Ball Nose End Mill Youtube

C4latb New Carbide Taper Neck Ball Nose End Mill For Aluminium Impeller Machining Mitsubishi Materials Corporation

Three Common Shapes Of End Mill Tool Engin Altintas 200112 Download Scientific Diagram

Ball Nose Milling Strategy Guide In The Loupe

End Mills The Essential Beginners Guide

End Mills The Essential Beginners Guide

Cft Systems Coolant Fed Tooling Systems A George Whalley Company Hurricane Solid Carbide Coolant Fed Ball Nose End Mill

1 2 Ball Nose End Mill Youtube

Ball Nose End Mill Cutter Puri Tools Steel Trader Mumbai India

1 8 125 Ball Nose End Mill Digital Wood Carver

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Micro Ball Nose End Mill Main Geometric Features Download Scientific Diagram

Common Types Of End Mills 3 1 Voxel Based Mrr Expression Of The Download Scientific Diagram

Basic End Mills Technical Information Msc Industrial Supply Co